Flexible PCB for Automobile Lights

Product Description

Automobile PCB, Flexible PCB for Automobile Indicator Lights

The Development of Consumer Electronics Industry Brings Infinite Business Opportunities for Flexible PCB

Consumer mobile electronic products based on smartphones and wearable devices continue to be miniaturized, light and thin, and automotive automation, networking, and electrification will create new demand growth points for the flexible circuit board industry. The FPC board is light, thin and flexible, and has the highest compatibility with wearable devices. It is the preferred connection device for wearable devices, and the FPC industry will become one of the biggest beneficiaries of the booming wearable device market.

Jinghongyi PCB, a professional automotive flexible PCB factory, provides a variety of PCB manufacturing services.

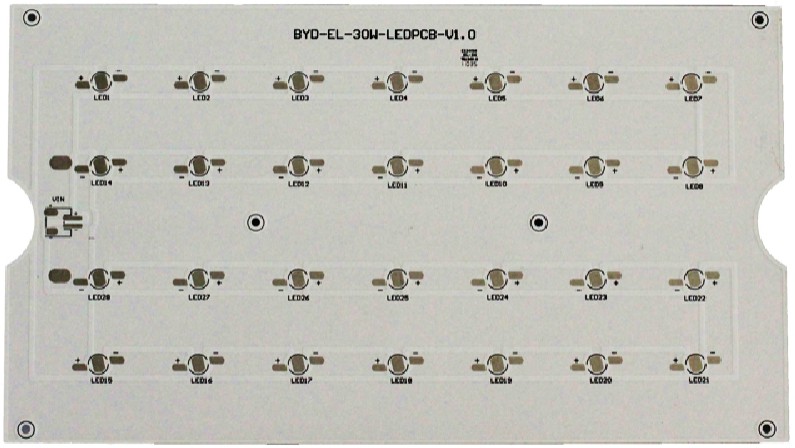

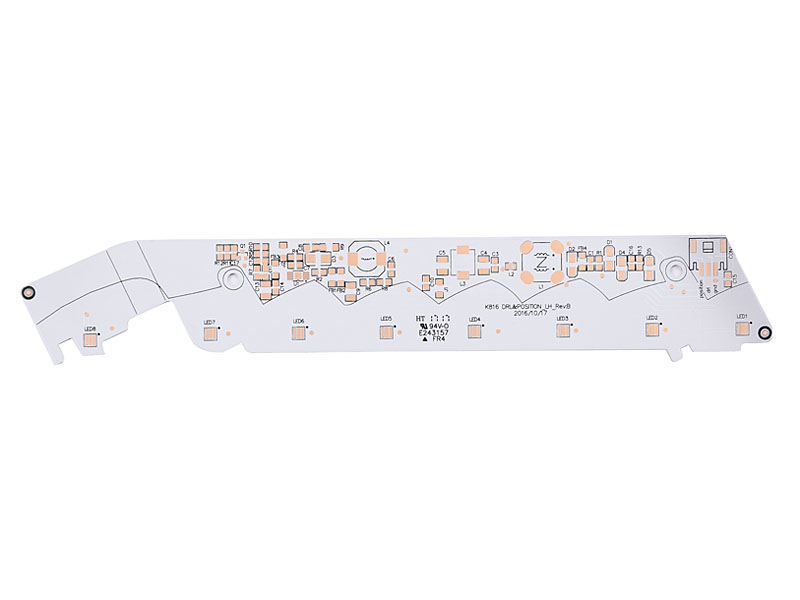

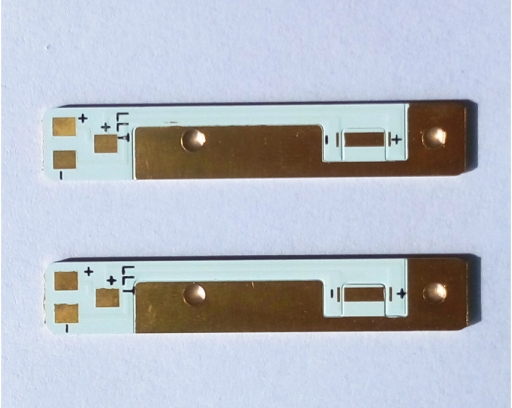

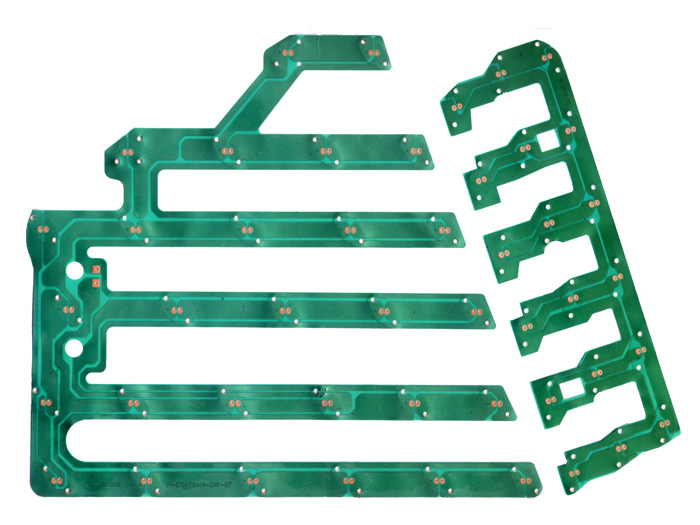

Car light LED double-sided flexible circuit board, car indicator LED single-sided flexible circuit board, automotive LED PCB, automotive FPC circuit board, vehicle flexible PCB, automotive lighting LED PCB, LED car light FPC Flexible circuit board, automotive lamp LED double-sided copper-based circuit board manufactured by Jinghongyi PCB, They all belong to the automobile PCB, used in daytime running lights, rear taillights, high-position brake lights and turn signals. The substrate is almost entirely made of PI, and the surface is divided into a solder mask such as a lamination film, a green oil, a white oil, and a butter. The structure is also divided into a patch LED lamp and a plug-in lamp bead. Because the appearance requirements of automobiles are getting higher and higher, the requirements of the lamps are increasingly demanding beautiful, light, thin, high brightness and long life. At present, FPC stickers LED lights have already replaced the traditional bulb lamp market, which has been plugged into the lamp market.

All enterprises are attaching importance to technology and quality. For Jinghongyi PCB, quality and technology are not the "object" to be promoted. It is the embodiment of the "future value vision" of Jinghongyi PCB itself.

The FPC production of Jinghongyi PCB, with product quality, promises to customers.

The quality of Jinghongyi PCB technology has been recognized not only in the domestic market but also in the global market. Jinghongyi PCB technology is becoming the leader of the FPCB industry. In the future, Jinghongyi PCB will develop into a global enterprise that plays a leading role in the FPCB industry market based on excellent human resources, top-notch production facilities, and leading quality competitiveness.

Single Side Flexible PCB

Single Side FPC is the most basic form of Flexible PCB, which forms a type of circuit on single-sided substrate Film with conductive copper foil or aluminum. Usually used as ables for connecting devices and devices and SubBoard for connecting with Main Board.

Double Side Flexible PCB

Copper foil is used on both sides of Base Film, and through Via holes are used to form the most common double-sided FPC flexible circuit board.

Multi layer Flexible PCB

Multilayer FPC refers to FPC products with more than three layers of flexible circuit boards. With the trend of high function and high density of electronic technology, Fine Patterns, and Laser Via Hole are becoming smaller and lighter. The application level of the Main Board and Touch Screen Board for general mobile products has gradually improved.

RFPCB Rigid-Flex PCB

Rigid-Flex PCB is the PCB that gives the advantages of Rigid PCB and Flexible PCB. In order to realize the connector connection between Boards, it is integrated PCB. At present, it is usually used in Camera Module and also in integrated MainBoard. Laser Via Hole Process is widely used.

Advantages of Flexible Circuit Board

Flexible printed circuit boards are printed circuits made of flexible insulating substrates, which have many advantages that Rigid printed circuit boards do not have.

1. Free bending, winding and folding, arbitrary arrangement according to space layout requirements, and arbitrary movement and expansion in three-dimensional space, so as to achieve the integration of component assembly and wire connection;

2. The volume and weight of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization, and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptop computers, computer peripherals, PDA, digital cameras and Other fields or products.

3. FPC also has the advantages of good heat dissipation and weldability, easy assembly and low comprehensive cost. The design of soft-hard combination also makes up for the slight deficiency of flexible substrates in component bearing capacity to a certain extent.

Main raw materials of FPC

Its main raw materials are right: 1, base material, 2, covering film, 3, reinforcing, 4, other auxiliary materials.

1. Substrate

1.1 Rubber Substrate

There are three main parts of adhesive base material: copper foil, glue, and PI. There are two kinds of single-sided base material and double-sided base material. Only one side of copper foil is single-sided base material, and two sides of copper foil are double-sided base material.

1.2 Rubber-free Substrate

The non-glue base material is the base material without the glue layer. Compared with ordinary glue base material, it has less middle glue layer, only copper foil, and PI. It has thinner, better dimensional stability, higher heat resistance, higher bending resistance, better chemical resistance, and other advantages than glue base material. Now it has been widely used.

Copper foil: At present, the thickness of common copper foil has the following specifications: 1OZ, 1/2OZ, 1/3OZ. Now, the thinner copper foil with 1/4OZ thickness is introduced. But at present, this kind of material has been used in our country and is being used in the ultra-fine line (line width and line spacing are below 0.05MM). With the increasing requirements of customers, this kind of material will be widely used in the future.

2. Covering film

There are three main parts: release paper, glue, and PI, which are only glue and PI in the final product. The release paper will be torn off in the production process and will no longer be used (there is foreign body on its protective glue).

3, reinforce

For the specific use of FPC materials, use in a specific part of the product to increase the support strength, make up for the FPC more "soft" characteristics.

At present, there are several kinds of commonly used reinforcing materials as follows:

1) FR4 reinforcing: The main components are glass fiber cloth and epoxy resin, which are the same as FR4 used in PCB.

2) Reinforcement of steel sheet: Composition of steel, with strong hardness and support strength;

3) PI reinforcing: The same as the covering film, there are three parts of PI and glued paper, but the PI layer is thicker, which can be produced proportionally from 2MIL to 9MIL.

4.Other auxiliary materials

1) Pure glue: This adhesive film is a kind of heat-curable acrylate adhesive film, which consists of protective paper/release film and a layer of glue. It is mainly used for laminating board, soft-hard bonding board and FR-4/steel sheet reinforcing board.

2) Electromagnetic protective film: paste on the surface of the board to shield.

3) Pure copper foil: only copper foil, mainly used for hollow board production.

There are six types of FPC:

A. Single-sided Flexible Circuit Board: Only one side has a circuit.

B. Double-sided flexible PCB: There are circuits on both sides.

C. Hollow-out Flexible PCB board: also known as window board.

D. Layered Flexible PCB board: two-sided circuits (separate).

E. Multilayer Flexible PCB board: two or more layers.

F. Rigid-Flexible PCB: Products Combining Flexible PCB with Rigid PCB.

At present, we are the main supplier of flexible circuit boards for smart wearing equipment. In addition, we also produce flexible circuit boards for 5G base stations, high-frequency PCB, high-speed PCB, radio frequency PCB, high-precision PCBs and Flexible Circuit Board Assembly services.

Flexible PCB Manufacturing Capability

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film | |

| Silkscreen Color | White, Black, Yellow | |

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

Product Categories : Flexible PCB